Lab Reports

Maratek Environmental Lab Reports

If you believe that your waste stream is out of the ordinary there is no need to worry. Maratek Environmental is able to perform, for a fee, feasibility tests on your liquid waste samples in order to provide you with the best solution.

Here is an example of a test performed by the Maratek Environmental labs.

CUSTOMER:

XYZ Paper Company

SOLVENT TO BE TESTED:

Solvent waste stream sample provided is purported to contain 7 main solvents – percentage of each is unknown. Solvents are:

| 1-Denatured Alcohol | (Comet UN-1170 – BP 79 oC, D = 0.791) |

| 2-Ethyl Acetate | (Comet UN-1173 – BP 77 oC, D = 0.902) |

| 3-sopropyl Alcohol | (Comet UN-1219 – BP 82 oC, D = 0.786) |

| 4-n-Propyl Alcohol | (Comet UN-1274 – BP 97 oC, D = 0.805) |

| 5-n-Propyl Acetate | (Comet UN-1276 – BP 102 oC, D = 0.888) |

| 6-Propyl Cellosolve | (Comet UN-1993 – BP 150 oC, D = 0.916) |

| 7-Mineral Spirits | (Comet UN-1268 – BP 195 oC, D = 0.786 |

| MSDS sheets were provided by XYZ Paper Company | |

OBJECTIVE OF TEST:

Recover solvents from waste stream. Observe if recycling requires vacuum and the form and quantity of residues. Determine best type of equipment to recycle waste stream at end user given solvent waste is generated at a rate of 90-gallons per day.

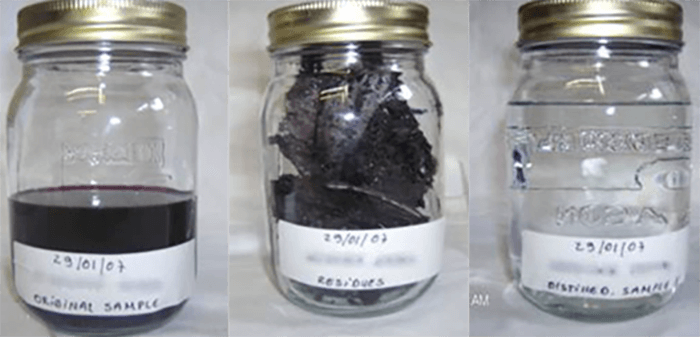

DESCRIPTION OF ORIGINAL WASTE STREAM:

| Appearance | Dark, opaque liquid. |

| Color | Black |

| Net Sample Volume | 13.1 liters |

| Net Sample Weight | 12.2 kg. |

| Sample Density | 0.94 kg/l |

SOLVENT TEST PROCEDURE

Using an Omega RS-6AV introduce complete waste stream sample for recycling. Begin with a low oil jacket temperature and no vacuum. Observe recovery, and slowly keep increasing oil jacket temperature. Once Jacket temperature reaches 180 oC and there remains solvent in the still process then switch to vacuum mode and again observe recovery. Objective is to distil all liquid & remain with residues only.

SOLVENT TEST SUMMARY

Volume to be tested: ≈ 13.1 liters

Equipment used : RS-6 (atmospheric pressure – vacuum system is disabled)

|

TIME |

THC |

THS |

VACUUM |

DISTILLATE |

COMMENT |

|

9:30 |

20 |

20 |

N/A |

NO |

Test Start |

|

10:25 |

74 |

70 |

N/A |

NO |

Few Drops |

|

10:45 |

80 |

71 |

N/A |

Clear Steady Flow |

In 8 min recovered 325 ml (2.4 l/hr) |

|

10:55 |

85 |

71 |

N/A |

Clear Steady Flow |

|

|

11:22 |

86 |

71 |

N/A |

Clear Steady Flow |

In 8 min recovered 325 ml (2.4 l/hr) |

|

11:31 |

95 |

71 |

N/A |

Clear Steady Flow |

|

|

11:46 |

95 |

72 |

N/A |

Clear Steady Flow |

In 3 min recovered 325 ml (6.5 l/hr) |

|

11:50 |

100 |

72 |

N/A |

Clear Steady Flow |

|

|

12:39 |

98 |

72 |

N/A |

Clear Steady Flow |

|

|

12:40 |

110 |

72 |

N/A |

Clear Steady Flow |

In 4 min recovered 325 ml (4.8 l/hr) |

|

1:00 |

112 |

73 |

N/A |

Flow Diminishing |

|

|

2:00 |

111 |

92 |

N/A |

No Flow |

Still shell empty. Only solid residues left in chamber |

| Total distillate recovered |

12.5 liters |

| Weight of recovered distillate |

10.6 kg |

| Density of recovered solvent |

0.85 kg / liter |

| Weight of residues |

0.18 kg |

RESULTS SUMMARY:

|

VOLUME (Liter) |

DENSITY (Kg/L) |

WEIGHT (Kg) |

% OF TOTAL WEIGHT |

|

|

ORIGINAL |

13.1 |

0.94 |

12.2 |

----- |

|

DISTILLATE |

12.5 |

0.85 |

10.6 |

87 |

|

RESIDUES |

---- |

---- |

0.18 |

1.5 |

|

TOTALS

|

10.78 |

88.5 |

||

RESULTS ANALYSIS:

It is obvious that from the test results that there was none – or very little – of solvents (3) to (7). Vacuum was never required to distil the complete solvent sample - although it is evident from the MSDS of solvent (7) that a vacuum would be needed. Furthermore the density of the distillate (0.85) demonstrates that the constitution of the distillate is weighted more towards solvent (2) and a mixture of the other solvents. Without a detailed chemical analysis it is impossible to have precise knowledge of the makeup of the distillate.

The total weight loss of 1.42 kg can easily be attributed to the following factors;

-

Weight of the samples taken during the test.

-

Losses in condenser coil.

-

Handling losses.

-

Instrument and measurement errors

There were no vapour emissions during the test.

From the results of the waste sample it seems that the residues constitute only 1.5% of the waste stream. This seems relatively low and should be considered as a low value for equipment selection.

In general the solvent waste sample provided distilled easily, providing a consistently clear distillate, free of cross-contamination and coloring.

The residues remaining following the completion of the distillation process were in solid form, indicating that the final equipment will need to either have a liner bag or an internal scraper. As to the vacuum, if future waste is identical to the sample provided, the final unit will not require a vacuum. However, if the waste stream to be treated will contain solvent (7) then a vacuum system will be required in the final unit.

Original -> Recovered Solvent -> Residues

Get a Free Solvent Recovery Trial of Your Solvent Waste Stream

We will process your solvent waste using Maratek’s patented solvent recovery equipment and provide you with the clean solvent to try in your operations.