Gun Wash is a popular and efficient solvent that is required in many industries such as automotive, kitchen cabinetry and millwork, as well as the painting industry. As this is a popular solvent, your company should strive to reduce and recycle gun wash waste.

The solvent recycling and recovery process will help your organization realize a range of benefits such as cost savings, and the ability to reuse the product using machines or services – where it comes back as a nearly virgin-quality product and is then ready for reuse.

What is Gun Wash?

Gun Wash is a solvent-based mix used for kitchen cabinetry, coatings, finishing, automotive, and manufacturing paint line industries. Lacquer thinner is used to clean spray guns, lacquer painting equipment and industrial scale paint lines. It is a budget friendly solvent that is needed in multiple industries.

What industries use Gun Wash?

Some examples of industries that use Gun Wash are:

- Painting

- Coatings

- Finishing

- Automotive

- Heavy Equipment Painting and Service

- Kitchen

- Cabinetry

- Millwork

Paint waste and lacquer thinners used in these industries as products require tools to apply paints, coatings and finishes which must be cleaned off with solvents. Gun Wash can clean the commercial painting and spray lines equipment.

The Gun Wash is used to clean spray guns and painting systems between different colors or after use. With spray guns in particular, the solution is sent inside and re-circulated through the gun to get the waste removed.

With other products, you immerse the tool that requires a cleaning, into the solvent and allow it to soak in there for about five to ten minutes. Once it is done soaking in the solution, take it out and let it dry. Gun Wash can be recovered and reused either with onsite equipment or off-site solvent recycling services.

When properly handled, up to 95% of the Gun Wash can be recovered and used again.

What is the process to recycle and reuse Gun Wash?

Once the Gun Wash has been used to clean the solvent waste/paint off, you then want to recycle the solvent by separating it from the waste, so that it can be used again.

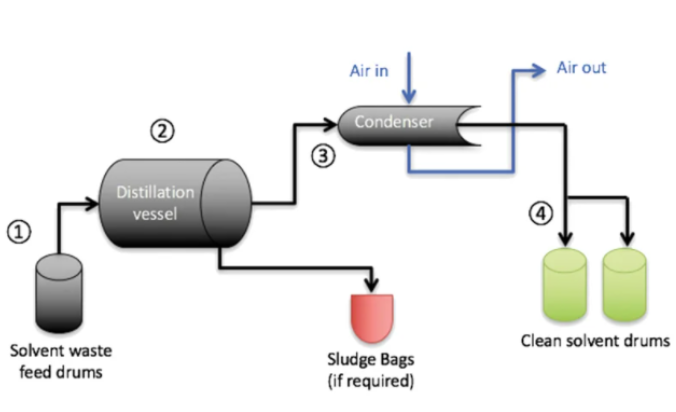

To do this, you can either do it manually, or use a machine that separates the solvent from the waste or paint using distillation and circulation. The waste is fed or poured into a distillation vessel. In the distillation vessel, it is heated using a thermal oil jacket that is electrically heated bringing the waste solvent to the boiling point. The pure solvent vapors are then channeled to an air-cooled condenser that is cooled back into a liquid form. That liquid is then discharged to a clean solvent collection container, where it can now be reused.

Gun Wash is a cleaning solvent that has many advantages, with the main one being that it can be recycled and reused – making it an environmentally-friendly option for your business. Your business will be helping the environment by reducing your company’s environmental footprint. The more recycled solvent you use, the less waste is sent for processing and destruction.

Recycling it is also cost-effective as you do not need to purchase new products over and over. Gun Wash is less flammable than a solvent like acetone, so it is considered a safer solution within the industry safety procedures.

Whether you have solvent recycling equipment on your property or hire out solvent recycling services – you are able to separate your waste from the solvent in order to keep reusing it. The recycling process can be done by Gun Wash users of all sizes, from a small paint shop with a single spray gun, to large scale industrial painting companies.

Maratek can offer on-site recycling equipment as well as off site recycling services throughout Southern Ontario. We can supply our Marasolve Gun Wash and pick up your used Gun Wash, saving you money on purchasing new products. Contact our team of experts today to find the best solution for your business.