Organizations and industries tend to use solvents that end up being spent and in need of disposal. An alternative for the disposal of the spent solvents is recycling them into a reusable source.

By recycling these solvents, companies can minimize the waste that they produce, as well as cut down costs on disposal expenses. Normally used in industrial applications, these solvents can be reused while also reducing the costs of transportation fees as well.

With regard to solvent recycling, there are a plethora of sustainable processes that can help companies, and various organizations maintain the safety of handling different solvents. This also applies to tracking regulatory compliance with transferring and recycling solvents as well.

The methods for recycling solvents

One method is known as tolling, which cleans the solvent to a predetermined specification, and then returns the solvent for the business to reuse. This is fairly common, as many companies use this process given its simplicity and effectiveness in determining which solvents can be used in the future.

Another method for recycling solvents would be beneficial reuse, which converts solvents into products for re-use as well, but specifically for manufacturing commercial products. This method provides a lot of benefits as well, given how much it helps minimize overall waste volumes.

Reclamation is another course of action that can be taken, where similarly to tolling, solvents are cleaned to a company’s specifications but instead are delivered to third parties who can use them as a replacement solvent.

Given how much waste can be produced throughout regularly scheduling manufacturing procedures, a lot of companies can see a noticeable decrease in certain costs pertaining to solvent recycling.

What equipment is needed for solvent recycling?

One of the most important aspects of reusing any type of solvent after it has been recycled is its purity. The higher a solvent is in its purity, the more effective it is in its use for whichever purpose it is needed for the company in possession of it.

Another aspect of solvent recycling to take into serious consideration is how contaminated the solvent is, and whether it can be deemed as reusable. In these instances, there are tools and machinery that can assist with allowing solvents to be recycled for various purposes. An example of these tools and machinery would be glass fractionating equipment, which assists in the separation of contaminants and other compounds that could negatively impact the effectiveness of the solvent.

How to handle and dispose of chemical waste

Managing the vast array of chemical waste that organizations find themselves using requires a commitment to the instructions laid ahead. To begin, identifying chemical wastes is the most critical step given that it includes flammable solvents, corrosives, reactive, toxic materials, and plenty more of the sort.

Another thing to note is to ensure that one does not mix incompatible materials together in a single container. Waste must be stored in containers in which the chemicals are compatible.

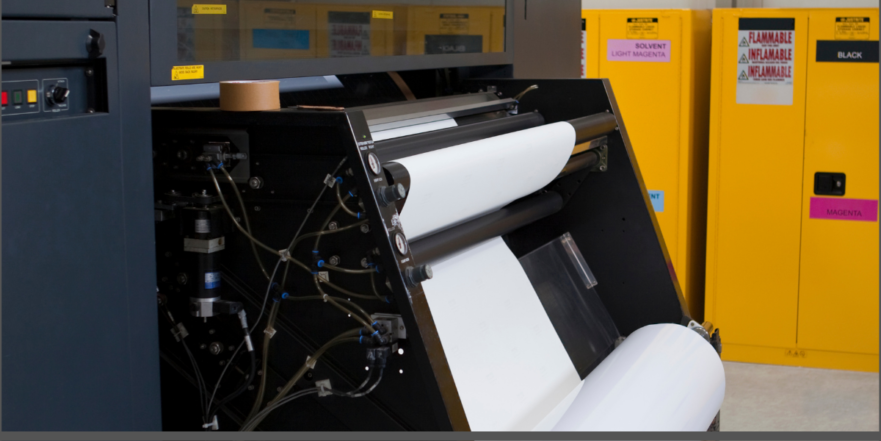

When handling solvents, safety cans can be used to collect and temporarily store large volumes of flammable organic waste solvents. This is effective considering how dangerous it is to mismanage the handling of certain solvents in an organizational environment. Albeit you can place flammable organic waste into safety cans, you cannot insert precipitates, solids, or other non-fluids wastes as well.

When handling waste containers, always ensure to attach a chemical waste label as well. All information on the label should be provided, as every detail with regards to it is crucial to the management of the materials inside. It is important to note also that all the safety precautions for handling and storing chemicals also apply to generated wastes as well. Another key point about the process of this is to ensure that wastes are segregated according to the compatibility groups, and not in alphabetical order.

Finally, always ensure that you dispose of aging containers promptly, and waste collection is done on a first-come-first-served basis.

Want to learn more about recycling or disposing of solvent waste?

Hazardous waste poses a threat to any environment and human health if they are treated improperly, and is typically generated by industry and manufacturing processes. These types of waste require special handling with how it is collected, stored, and transported in order to reduce the adverse effects on those around it.

This also means that companies generating recurring hazardous wastes are under pressure to comply with regulations, along with having to reduce operating costs to dispose of or recycle responsibly in an environmentally-friendly manner.

However, most solvents have no substitute, so companies often tend to find difficulty in ways to dispose of hazardous waste.

To learn more about hazardous waste or solvent recycling, and effective ways in improving your practice of managing them, get in touch with the Maratek Environment team today. We’d love to help find a solvent waste recycling or disposal solution that works for your business.