Methyl Ethyl Ketone (MEK) is a liquid industrial solvent that is highly efficient and used mainly for surface coating.

It can also be used as an extraction medium for fats, oils, waxes, and resins. Some of the benefits of MEK are that it has a slow evaporation rate, high solvency, low boiling point, and low viscosity.

In this blog, Maratek Environmental looks at the industries that MEK can be used in and how it can be recycled or recovered for reduced business costs.

What Industries use MEK?

Although MEK is flammable, and has some explosive properties to it, it is a widely-used industrial solvent.

It is common in most lacquer thinners and has a similar function to acetone in that it produces a strong cleaning product, due mainly to its slow evaporation rate. It is seen as a stronger cleaning agent than acetone as it has the higher boiling point between the two.

It forms an azeotrope with water, meaning that the MEK solution and water both reach a constant boiling point. This makes it useful when distilling moisture to some applications, since the water is absorbed by the MEK. Some examples of industries that use MEK are:

- Surface coatings – Used to thin paints and clean equipment like spray guns, brushes, and paint lines.

- Adhesives – Used to clean and remove adhesives from surfaces.

- Printing inks – Can be used to conduct a deep clean of printing presses.

- Automotive and electronics industries – Used to clean surfaces prior to powder coat applications and industrial equipment cleaning.

- Aerospace – Used in reducing paint and cleaning paint from the manufacturing process.

- Manufacturing – Typically used as a once or twice per year as a deep cleaning solution for industrial equipment.

What is the process to recycle and reuse MEK Solvent?

Recycling and re-using your MEK solvent is cost-effective and, with the right equipment, easy enough to do. It reduces your solvent waste costs, and instead of buying brand-new virgin solvent, you can just reuse your recycled solution. In fact, you are able to recycle up to 95 percent of your waste solvent stream.

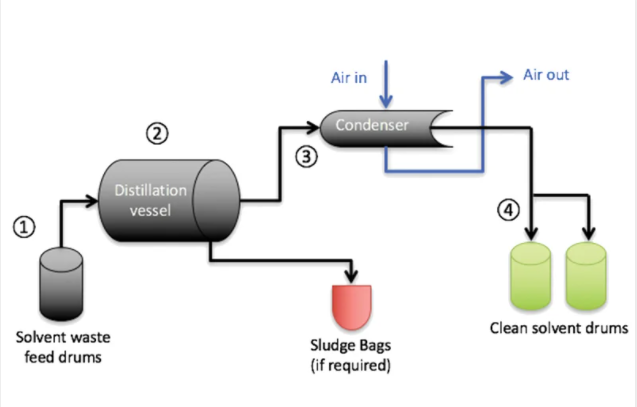

Here’s how the Maratek solvent recycling machines work

First you feed your waste solvent into a vessel. The vessel uses a thermal oil jacket, heated by electric heaters, to bring the MEK to its boiling point. The vapors then go towards an air cooled condenser, which allows the vapors to cool into a liquid form. This liquid is then pushed through to the clean solvent collection drums and is ready to be reused.

MEK vs. Acetone

As both MEK and Acetone share the same ketone trait, it is assumed that both solvents are interchangeable with the other.

However, that is not the case – MEK is a stronger solvent than acetone. This is because MEK has a slower evaporation rate and boils at a higher temperature than acetone. MEK is also less soluble and less volatile than acetone. Acetone is very fast drying, and is often used as a paint thinner.

Acetone is not considered to be a volatile substance, though its low boiling point makes it more flammable than other substances. It is also used more often for consumer products such as nail polish remover, rather than industrial.

Why you should recycle your MEK solvent

MEK can be dangerous, however it is a necessary solvent in several industries. With prices on virgin solvents rising, recycling your waste solvents is a great practice both economically, environmentally, and when dealing with safety and compliance.

MEK recycling equipment provides waste management by separating the waste from the solvent, making it completely reusable.

It also minimizes the disposal costs. After you have used MEK, you will find that it is difficult to get rid of, as it is considered hazardous waste. Recycling reduces that impact by using the recycled material as much as possible before you need to dispose of it – saving your business time and money.

In Canada, Hazardous waste legislation works to prevent any pollution from the material, while protecting both human health in surrounding areas of the disposal, and the environment. This makes regulations around waste disposal very strict. As a company, you are able to support green initiatives by implementing a recycling and reuse program for your MEK hazardous waste.

Want to learn more? Maratek is a world leader in the manufacturing of liquid waste recycling and recovery equipment. Get in touch with our team of experts today. We would love to answer any questions that you may have.